TEBA

Dye House Smart Solutions - Taiwan's Textile Innovation

Logic Art's Smart Dye House solution revolutionzed the production flow of textile industry.

流亞科技的智慧自動化染整方案,顛覆紡織業的生產流程。

2024.11.26

Dye House Smart Solutions - Taiwan's Textile Innovation

領先全球的智慧自動化染整

In the global synthetic fiber market, Taiwan ranks third, with a remarkable market share of 70% in functional fabrics. This success stems not just from a comprehensive supply chain and non-stop innovation, but crucially a key manufacturing process: dyeing. Logic Art’s smart solutions for dye house have transformed the processes from the traditional "spoon master" era—where workers manually mixed dyes—to single-machine automation and connected production lines. The smart solutions conserve water and dye materials as well as turn the production site into a pleasant working environment just as clean as office spaces.

在全球化學纖維市場,台灣排名第三,機能布料市占率更高達七成,原因除了上下游供應鏈完整、研發推陳出新,還有一個最重要的關鍵製程—染整。流亞科技的自動化方案,紡織業的染整製程,從古早的「湯匙仔師」(手動調配染劑)演進到單機自動化及產線機聯網,不止省水省染料,更讓生產現場乾淨得像辦公室。

Five engineers started their business with a controller, and their original metering system has been selling like hotcakes ever since.

5名工程師創業從控制器起家 獨創計量系統熱賣到現在

流亞科技於1993創立,流亞科技董事長陳暐仁表示,創業最初是5個工程師,具備軟硬體、機電整合的背景,有志一同想要創業,但礙於旋轉門條款2年內不能從事染整產業,因此從控制器核心出發,進而切入更各產業工業電腦應用。

陳暐仁坦言,當初大家本來不想再做染整業,但因朋友請託做出的染色註記計量系統,做好後效益非超高,透過註記標準化,對產業幫助非常大,成為全球染整產業的必備產品,到現在還是熱賣。透過以控制器為核心優勢,發展智慧製造總體解決方案,改變傳統產業固有模式,進而為客戶打造智慧生產模式和ESG解決雲端方案。

Logic Art was founded in 1993, Logic Art's Chairman Tony Chen said that the venture was initially five engineers, with hardware and software, mechanical and electrical integration of the background, the desire to start a business together, but due to the terms of the revolving door can not be engaged in the dyeing and finishing industry within two years, so the core from the controller, and then cut into the more industrial computer applications in various industries.

Tony frankly said that at the beginning, we originally did not want to do the dyeing and finishing industry, but because of a friend entrusted to make the dyeing registration measurement system, after doing a good job of non-super high efficiency, through the standardization of registration, the industry is very helpful, and become the global dyeing and finishing industry must have products, and now is still a hot seller. By taking the controller as the core advantage, we develop the total solution of intelligent manufacturing, change the inherent mode of traditional industry, and then create

intelligent production mode and ESG cloud solution for our customers.

Taiwan's Functional Textiles Becomes the Driver of 70% Market Share, Textile Dyeing and Finishing Sites Become Cleaner

打造台灣機能紡織7成市佔推手 紡織染整現場變乾淨

台灣紡織業在70年代蓬勃發展,當時佔總出口額達30%,是外銷產業之冠,但因應產業轉移國外生產,台灣需透過「機能」、「環保」、「永續」朝向「高科技化」定位的紡織業邁進。

陳暐仁指出,台灣紡織供應鏈海內外產值超過兆元,貢獻外匯排名第4名,其中機能性紡織品全球市佔率70%,化纖全球排名第3、整體紡織出口排名為全球第8位。全球紡織產業中,台灣具備上下游供應鏈完整,且有優異機械設備及機電整合實力,加上研發創新能力,造就極具競爭優勢的產業聚落。

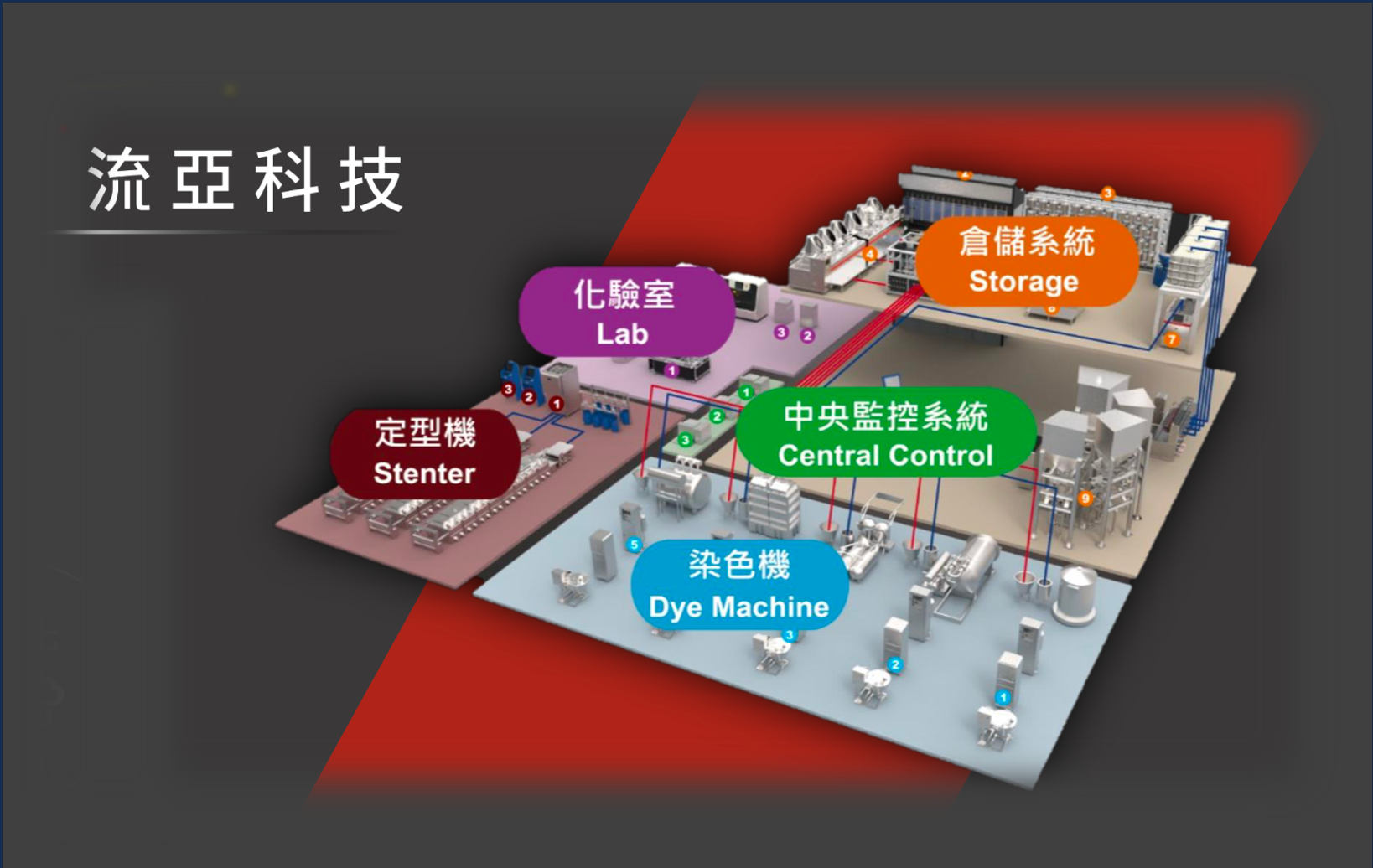

紡織業製程可分為,原物料、抽紗、織布、染色、成衣、包裝、品牌到後端銷售,流亞科技在紡織染整過程中,提供自動化解決方案,達到品質穩定,一次成功率、交期準時,讓紡織業染產做出差異化,也是提高附加價值的重要環節。

流亞科技品牌三大優勢就是研發創新、客製化創新、全球在地化服務、也因次蕴育出企業口號「We define the One」,與客戶定義出專屬的方案,像是紡織股王儒鴻就是其客戶。而2001年打造的滴液機擁有全球專利,也是全球最有競爭力設備,高精密劑量的製程,讓染料調製精準誤差小於0.02克。

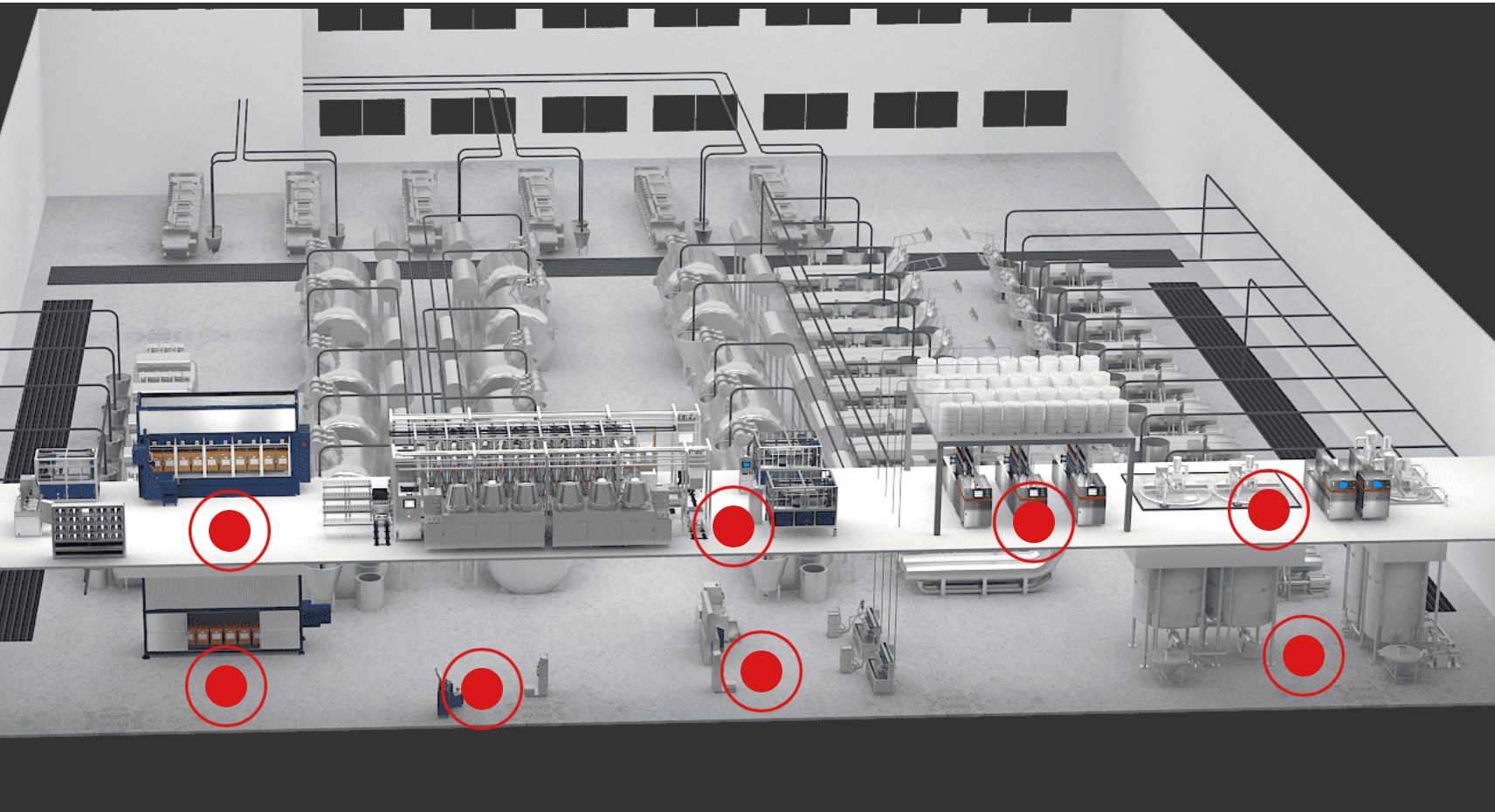

流亞科技解決染整每個階段的痛點,一塊布要染色,首先會把顏色工藝製程找出來,化驗室與全球色彩公司結合,在化驗室找完備方後,用滴液機把顏色滴出來,用電腦控制所有的染色機,也支援染料化學品註記供料系統,完全無人化。揮別早年需動用「湯匙仔師」(手動調配染劑)不精確、效率不佳的問題,也能讓染整環境更乾淨。

而自動化數位轉型過程中也延伸至ESG層面,染整現場可從單機化到機聯網,透過數位控制中心「IDCC系統」,可因應ESG碳盤查,所有設備數據採集可視化後,也可進行數據分析來做智慧決策,後續提供的紡織雲平台的SAAS服務,也讓數據化能源管理能達成。

Taiwan's textile industry boomed in the 1970s, when it accounted for 30% of total exports and was the top export industry. However, due to the transfer of industries to overseas production, Taiwan needs to move towards a “high-tech” textile industry through “functionality,” “environmental protection,” and “sustainability.

Tony pointed out that the domestic and foreign output value of Taiwan's textile supply chain exceeds one trillion dollars, contributing to the 4th place in foreign exchange ranking, of which 70% of the global market share of the functional textile products, the 3rd place in the global rankings of chemical fibers, and the overall ranking of the textile exports for the 8th place in the world. In the global textile industry, Taiwan has a complete upstream and downstream supply chain, excellent machinery and equipment, mechanical and electrical integration strength, and R&D and innovation capabilities, creating a highly competitive industrial cluster.

The textile manufacturing process can be divided into raw materials, spinning, weaving, dyeing, garments, packaging, branding, and back-end sales. In the textile dyeing and finishing process, Logic Art provides automated solutions to achieve stable quality, one-time success rate, and on-time delivery, which allows the textile industry to differentiate its dyeing products and is an important part of increasing value-added.

The three strengths of the Logic Art brand are R&D innovation, customized innovation, and global localized service, which has led to the corporate slogan, “We define the One,” which is used to define customized solutions with customers, such as textile stockholder Wang Ru-hung, who is one of its customers. The drip machine built in 2001 has a global patent and is the most competitive equipment in the world. The high-precision dosage process allows the dyes to be adjusted with an error of less than 0.02 grams.

Logic Art solves the pain points of every stage of dyeing and finishing. When a piece of cloth is to be dyed, the first step is to find out the color process, and the laboratory is integrated with a global color company. After the laboratory has found the preparation, the color is dripped out with a liquid-dripping machine, and all the dyeing machines are controlled by computers, which also supports the dye-chemical registration and feeding system, which is completely Inhumanized. This eliminates the problems of inaccuracy and inefficiency of the “spoon-master” (manually mixing dyes) in the early years, and makes the dyeing and finishing environment cleaner.

The process of automation and digital transformation also extends to the ESG level. Dyeing and finishing sites can be transformed from stand-alone machines to machine networks, and through the digital control center “IDCC system”, ESG carbon inventories can be carried out, and after the data from all the facilities is collected and visualized, data analysis can be carried out for making intelligent decisions, and the subsequent provision of the textile cloud platform's SAAS service also enables data-based energy management.

The layout of Logic Art's Dye House Smart Solution.

流亞科技的智慧自動化染整方案。

Forming an “A team” in the textile industry to lead Vietnam's Great Leap Forward to India

組建紡織業的「A team」打天下 帶領越南大躍進前進印度

隨著紡織產業移轉至東南亞,1998年流亞科技就到泰國設立公司,是紡織前輩提攜前進泰國,結合5家設備業者結盟打天下。2019年因中美貿易關係,產業進一步轉進越南,為打響知名度,憑藉經濟部國際市場補助計畫,結合泰國的結盟經驗,打出「越南大躍進」計畫,包括:染整機台廠、染色機台廠、定型機、染料廠、後整理加工廠,組成「A team」與官方越南商工聯合會(VCCI) 、越南紡織服裝協會(VITAS)成功對接。

就像自行車產業組成紡織業越南的「A Team」的概念,紡織產業也集合起來要打群架,團隊一起幫忙規劃,將台灣整體解決方案完整端上桌,才能抵擋紅色供應鏈,越南「A Team」非常成功,更發揚光大也將「A Team」複製到印度。

陳暐仁坦言,流亞科技印度經營已超過20年,但鑑於中美貿易戰,印度的紅色供應鏈可能會對產業競爭力造成打擊,因此決定重新聚焦經營策略,透過品牌重新定位、數位行銷先行下,今年6月印度客戶在展會中拜訪流亞攤位到訪率達26% 。

後續印度台灣代表處也邀請流亞科技針對智慧製造,分享經驗後,10月印度聯合工會CII組團參觀紡織業「A Team」,成功與官方對接後,透過社群口碑擴散,建構了印度示範場域累積訂單也超過300萬美元,對「A Team」是很大的鼓舞。

As the textile industry shifted to Southeast Asia, in 1998, Logic Art set up a company in Thailand, which is a textile predecessor to Thailand, combined with five equipment manufacturers to form an alliance to fight for the world. 2019 due to the trade relations between China and the U.S., the industry has further shifted to Vietnam, and in order to create awareness, with the Ministry of Economic Affairs' international marketing subsidy program, and combined with the alliance experience of Thailand, we have launched the “Great Leap Forward in Vietnam” plan, including: dyeing and finishing machine factory, dyeing machine factory, fixing machine, dyes factory, and finishing factory. The “A team”, which includes: dyeing and finishing machine, dyeing machine, sizing machine, dyestuff factory, and finishing factory, has formed a successful connection with the official Vietnam Chamber of Commerce and Industry (VCCI) and the Vietnam Textile and Apparel Association (VITAS).

Just like the bicycle industry to form the textile industry Vietnam's “A Team” concept, the textile industry also gathered to fight, the team together to help plan, Taiwan's overall solution to the table, in order to resist the red supply chain, Vietnam “A Team” is very successful, and carry forward the “A Team” also copied to India.

Tony admitted that Logic Art has been operating in India for more than 20 years. However, in view of the trade war between China and the US, the red supply chain in India may impact the competitiveness of the industry, so LASIK has decided to re-focus its business strategy through brand repositioning and digital marketing. In June of this year, 26% of Indian customers visited Lumia's booth at the exhibition.

Subsequently, the India-Taiwan Representative Office also invited LASOTEK to focus on smart manufacturing and share its experience. In October, a delegation from the United Indian Trade Union (CII) visited “A Team” in the textile industry, and after successfully connecting with the officials and spreading through word-of-mouth in the community, it constructed a demonstration site in India with accumulated orders exceeding US$3 million, which was a great encouragement to “A Team”.

India textile industry delegation visited Logic Art.

印度紡織公會來台指定參訪流亞科技。

撰文:TEBA 台灣精品品牌協會

Written by TEBA(Taiwan Excellent Brand Association)

contact TEBA for more Taiwan brands: jennylo@teba.org.tw